Metal Finishing

For any services of interest to you, please contact us for further information!

VAPour honing/blasting

Deburr and Surface Finish

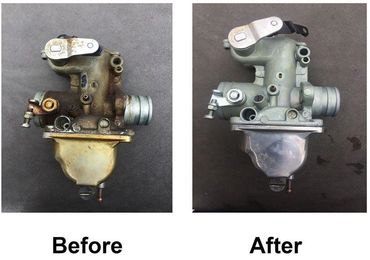

Vapor blasting is quickly becoming the top choice for achieving high-quality surface finishes. Our Vapor Honing offers a dust-free solution for degreasing and blasting industrial components of various shapes and sizes. The key to vapor blasting is the flow of water-borne abrasive, which produces a finer finish and eliminates the impregnation of media into components. Our service is perfect for restoration of old and corroded parts and a customer favourite for those working on older vehicles.

deburring

Vibratory Rumbler

Our in-house vibratory rumbling service delivers a consistent, high-quality surface finish across a wide range of components. Ideal for deburring, edge rounding, and polishing, this process enhances both the aesthetic and functional performance of parts—particularly in precision-critical sectors like motorsport, aerospace, and defence. By streamlining post-machining refinement, we ensure parts are ready for inspection or assembly with minimal delay, while maintaining tight tolerances and surface integrity. It's a cost-effective way to elevate quality without compromising speed.

Shotblasting

Shotblasting

Our shot blasting service provides a clean, uniform surface finish that’s ideal for preparing components for coating, painting, or inspection. By removing scale, rust, and machining residues, it enhances both the appearance and performance of parts—especially in demanding sectors like aerospace, defence, and automotive. Performed in-house with controlled media and pressure settings, our process ensures consistent results across batches while preserving dimensional accuracy. It’s a fast, reliable way to improve surface adhesion and extend component longevity.

Ultrasonic Cleaning

Ultrasonic Cleaning

Our ultrasonic cleaning service uses high-frequency sound waves and specialist cleaning solutions to remove contaminants from complex and delicate components. It’s particularly effective for reaching internal cavities, blind holes, and fine geometries that traditional methods can’t access. Performed in-house, this process ensures parts are thoroughly cleaned without abrasive contact—preserving surface finishes and dimensional accuracy. Ideal for aerospace, medical, and precision engineering applications, ultrasonic cleaning supports high inspection standards and reliable downstream performance.

Surface Treatments

Chemi-Blacking

Developed as a more environmentally friendly version of traditional gun blackening, blueing and parkerising, our cold oxide blackening process will blacken ferrous metals; mild steel fastenings and brackets. Oxide blackening increases the corrosion resistance of treated parts which can be maintained through regular application of our Sealer or through the use of the de-watering oil.

Photo gallery

Copyright © 2025 iconicengineeringsolutions.com - All Rights Reserved.